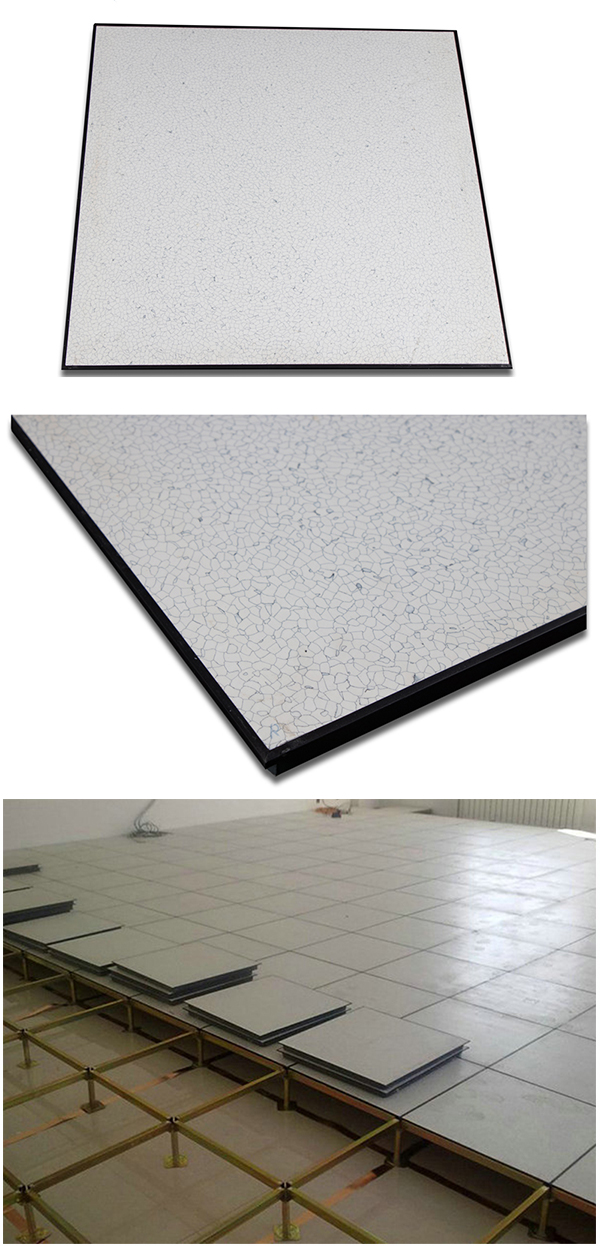

Our Jinhai factory mainly produces static conductive PVC flooring. People usually use the floor as a direct anti-static floor or as a veneer (PVC panels). Or they lay the finish as various anti-static floors, such as the all-steel anti-static floor, wood based floor, calcium sulfate panel, aluminum alloy anti-static floor, etc. This anti-static raised floor is a kind of overhead and interchangeable functional floor, also known as ‘raised floor’.

How high is the anti-static raised floor above the ground? If the project does not have a specified height, will the purchaser have certain doubts? Yes, the general purchaser will be very confused when encountering this situation. Because there are several options for height, which our anti-static floor manufacturers do not determine. Then what factors affect how high the anti-static floor is from the ground?

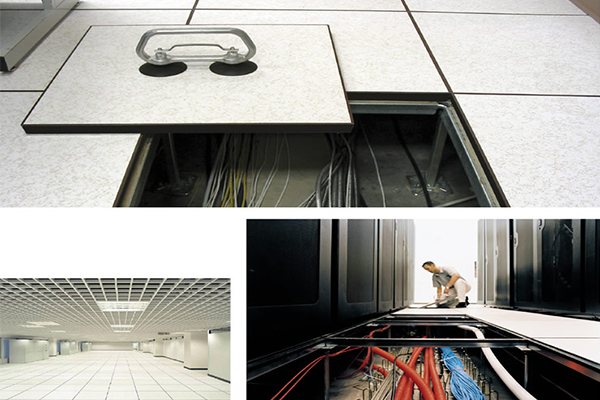

Here we Jinhaifloor will give you a popular science. Why should the floor be raised? The raised floor is conducive to the ground space. There can be extra space at the bottom of the floor for wiring and other concealable wire boxes, etc. The factors that affect the height are the bridges, wiring, and other concealments at the bottom device.

According to the feedback of our installation workers, the more commonly used anti-static raised floor heights are 15cm, 20cm, 25cm, and 30cm. For example, small and medium-sized computer rooms, central control rooms, monitoring rooms, etc. However, the actual situation still depends on each enterprise according to the requirements! However, if the client does not require it, it is best to use a height of 15-20CM. But now there is no wiring bridge at the bottom, and this height is also convenient for future changes.