These days manufacturing units are required to follow stringent safety regulations in order to prevent incidents. As these areas are prone to accidents, they impose adverse effects on equipment, products, workers, and components. However, that doesn’t mean you cannot find a resolution. ESD tiles for electronic manufacturing units are highly popular to preserve these incidents and further strengthen the protection. By managing the flow of static energy in the floors, these tiles promote safety in risky environments.

Why You Need ESD Tiles for Electronic Manufacturing Units

You can find various reasons to deploy ESD tiles, however, the foremost reason is their utility in environments discharging static energy. Electronic manufacturing units usually have microelectronic fabrication facilities, manufacturing rooms, box build, and more. The flow of static energy increases with the extensive use and implementation of electronic equipment. Hence, the requirements of ESD Tiles for electronic manufacturing units becomes crucial.

Static discharge may cause major damages in the microcircuits due to untimely spiking of electric current. This minor damage can create major havoc in electronic manufacturing units. Hence, the use of ESD tiles for electronic manufacturing units prevents such damages. ESD floors are equipped with technique as mentioned below:

- Creates a traceable track to the ground with a minimum of similar to 1 billion ohms capacity.

- Resists static discharge above 100 volts. This may happen due to the generation of the energy that takes place through traffic on the floor.

How do ESD Floors work?

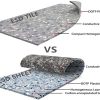

The ESD floors persist conductive elements. These elements are made of carbon fibres and other likely particles. With the use of ESD tiles, you will be able to transport the static energy into the ground. With a thick surface, ESD tiles for electronic manufacturing units promote unifying underlayment. This underlayment keeps the static current away from the reach of the immediate floor. Further, it connects with the ground.

All the floors persist a specific degree of resistance towards electrical discharge. However, the reason you need to choose ESD tiles is because of its higher capacity to resist static discharge. ESD tiles for electronic manufacturing units have better conductivity. Hence, meets the protocols of the safety requirements. The use of power equipment becomes safe with these tiles.

Exclusive Use Of ESD Tiles for Electronic Manufacturing Units

Apart from safety, there are other benefits of ESD tiles. The ESD tiles promote efficiency in the performance and further secures greater advantages. The glossy ESD Tiles can promote visibility in areas comprising delicate and small elements. The focus also gets increased in such areas. Various guidelines suggest that manufacturing units must segregate areas through labels and as per departments. The use of ESD floors in hazardous zones will highlight them for cautious actions. Also, you can use color options to highlight the section.

ESD floors are not just suitable for electronic manufacturing units but also for data centers and other spaces with high traffic. Static discharge is optimum in high traffic areas, hence the use of ESD tiles would aid dispersion. Also, this will enhance the life of the machinery and make it more study.