Anti-static principle <1>

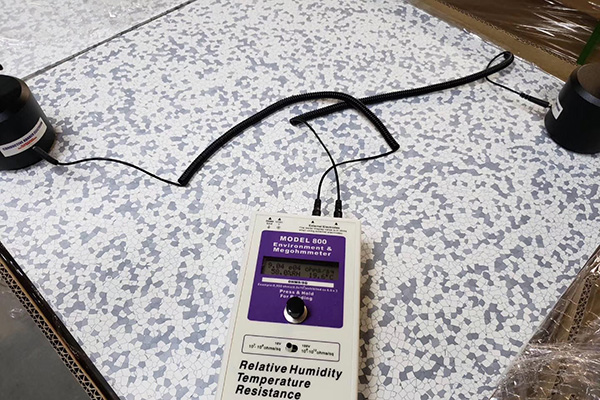

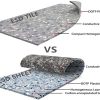

The anti-static floor can guide the static charge of people or equipment and the charge of air to the ground in time. So that the accumulated static electricity will not affect the product and play a role in protecting the product. ESD flooring anti-static test is very necessary. Use a surface resistance tester to measure the resistance between two points on the anti-static floor and the resistance between one point on the floor and the ground point. Then compare the measured resistance value with the standard value. Judge whether the floor anti-static performance is good and whether it meets the anti-static requirements.

Anti-static principle <2>

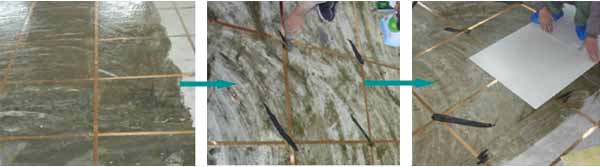

a. Lay copper strip on the cement floor. Apply a layer of insulating glue to facilitate adhesion between the floor and the cement floor;

b. Apply the adhesive mixed with conductive material on the connection point of copper strip;

c. Lay the floor on the cement floor, at this time, the copper strip and the floor are fully connected and conductive.

Anti-static Test Method

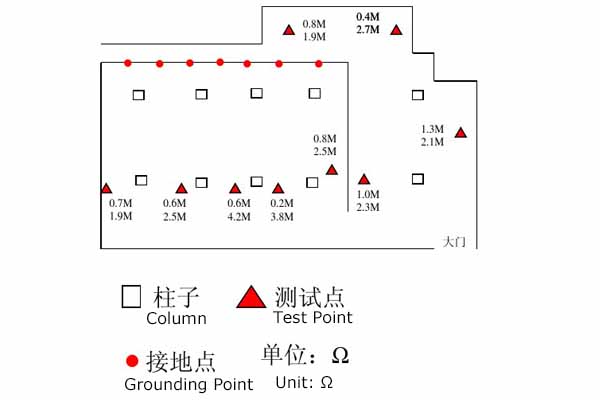

a. Use the columns and walls in the plant to divide the plastic-encapsulated plant into six areas, and select 1-2 measurement points for each area;

b. Measure the resistance between each point and the grounding point, as shown in the figure on the following page;

c. Measure the resistance of each point and the adjacent floor, as shown in the figure on the next page;

d. Measure whether the resistance between the two grounding points is zero, and judge whether there is continuity between the grounding points;

e. At the same time of measurement, record the measurement results – and pay attention to the unit

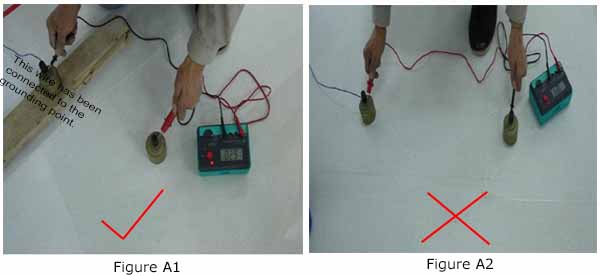

A. Measure the resistance between the floor and the grounding point

Figure A1 is the correct method for measuring the resistance of the floor and the grounding point. When measuring, the terminal connected to the grounding point must be placed on an insulator such as wood. And the other terminal is in full contact with the floor. At this time, the resistance displayed on the surface resistance tester is the resistance of the floor and the grounding point;

In Figure A2, because the terminal connecting the ground point and the floor have been connected, the resistance displayed on the tester is not the resistance of the floor and the ground point.

B.Measure the resistance between two adjacent points on the floor

When measuring, place the two terminals on the two adjacent floors, and measure the resistance between the two points with a tester.

Because the copper strip under the floor is a grounding grid connected to each other, if one of them is not connected to the copper strip to conduct electricity, the resistance measured at this time will be larger.

C. Anti-static test between the two ground points

When measuring, fully contact the two probes of the surface resistance tester with two grounding points respectively. And measure the resistance between the two points.

Multiple grounding points are led out from the conductive copper strip laid under the floor. If the copper strip forms a closed-loop network, the resistance value measured at any two grounding points shall be zero.

D. Measure the resistance between the grounding point and the earth

The resistance between the grounding point and the ground cannot be measured temporarily due to the construction of the plant.

Analysis of Anti-static test results

The JEDEC standard stipulates that the standard value of resistance between the anti-static floor and the grounding point is 104~106Ω. Compare the measured resistance value with the standard value one by one. If the measured resistance of the anti-static test is within the range specified by the standard, it is judged that the floor anti-static index is qualified.