New project finished installation at the beginning of June with our Jinhai flooring. (Feedback by our Korea clients).

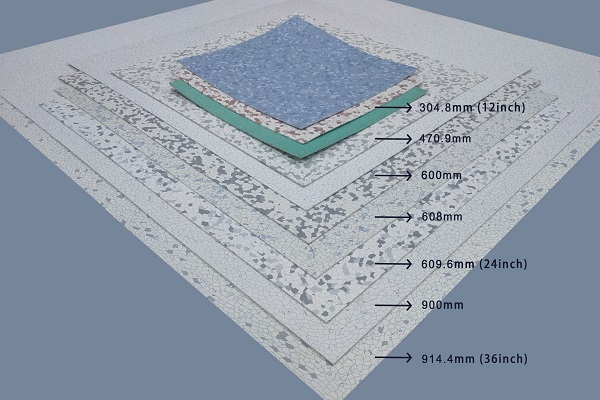

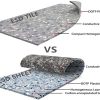

This is the process of installing antistatic floor tiles for electronic parts handling factories and laboratories. Project areas about 220m2.

Here are the steps of the installation as reference:

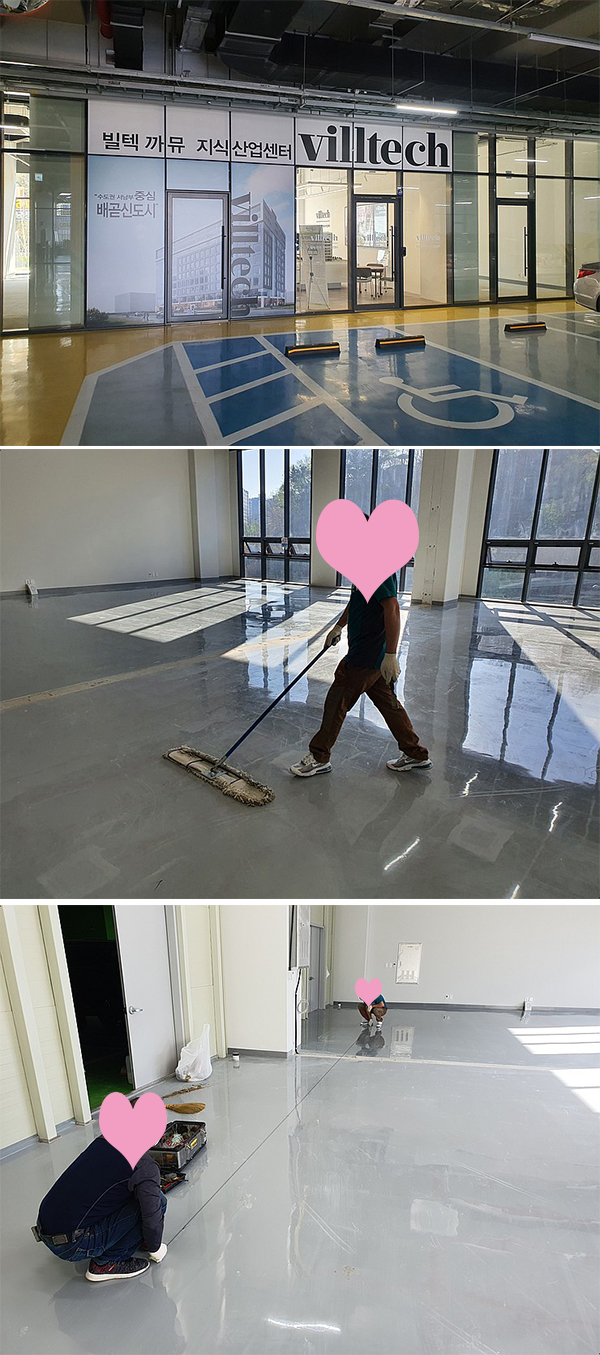

Step 1:

Clean the construction site:

Step2:

Spread the conductive adhesive evenly on the floor and cure for 10 to 20 minutes.

Wait for the adhesion to rise.

Step3:

Glue the tiles, and put copper strips inside the antistatic tiles to ground.

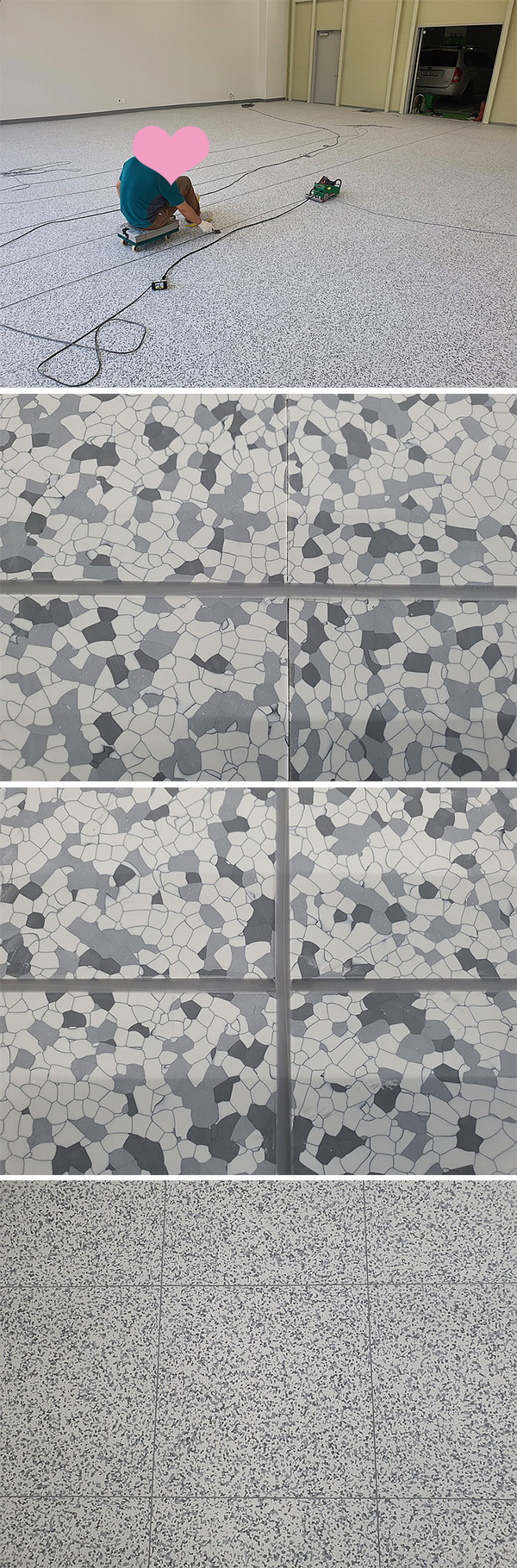

Step4:

Use a tile V-shaped cutter, cut about 2/3 of the floor to open V-Shaped groove.

Step5:

Laying welding rods

Step6:

Test electronic resistance

Welcome to visit this link about electronic resistance test:

https://www.youtube.com/watch?v=fy4hCQCPjq8

Step 7:

Remove the dust on the installed antistatic tile and cover it with conductive wax

About detailed installation, welcome to visit this video:

https://www.youtube.com/watch?v=3E69wAQDbec

Should you have any question about installation or the antistatic tiles, please feel free to contact us.