The conductive flooring system provides the lowest charge generation and quick charge dissipation for an ESD production atmosphere.

Firstly, a conductive flooring must meet a completely different standard than conventional floor coverings. This type of floors is designing to withstand heavy machinery or long-term, heavy-weight storage.

Conductivity is the term that refers to the ability of a material to conduct an electric current or “die to the ground”.

An electric current is a quantitative measure of the amounts of charged particles that pass through a medium. However, for an electric current to create, there needs to be an electrical signal with a potential difference between two points.

Conductive flooring

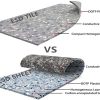

In this flooring, with a few small exceptions, polymers are insulating and therefore do not conduct electricity. This occurs with synthetic resins used in construction. Whatever the layer thickness of the pavement, its resistance to earth. This means that conductive aggregates must add always in the formulation of these materials.

Conductive flooring can design in two ways

– In the first, the conductive coating ensures that any load drives to the ground over any distance. Because a conductor’s resistance is proportional to its length, ground resistance levels vary accordingly.

– In the second, the above thing avoids by designing the coating in such a way that its conductivity is only sufficient to drive the electrical charges down through the layer itself. For example, between 0.5 and 5mm according to the type of structure.

Here, the current absorbs by a layer with much less resistance and is quickly discharging along with it to the grounding points. Because the resistance of the coating layer and the conductive layer differ by a power of at least 10.

It is very important to apply conductive flooring and dissipative syste

ms on perfectly level surfaces. This is because conductive layers can guarantee their perfect operation if they have a specific and well-defined thickness.

For which room conductive flooring is suitable?

The conductive flooring is an electrostatically dissipative flooring system. This system was developed for use in places where components must protect against the risk of electrostatic discharge. This includes areas with electronic subassemblies or devices in which flammable or explosive materials are using. Typical examples of this are productions for electrical components or clean rooms.

Things to consider while installation

If you are planning to install conductive flooring, you should pay attention to the following points:

– Always keep the ground sanitation.

– Consider good protection against shielding.

– Make sure to level the ground and the line power supply is perfect.

– The installation of the flooring should be firm and stable.

– The flooring edge should be in a straight line.

In conclusion, we at xueyanfloor.com, are a specialist in the development of ESD flooring and offers individual floor solutions. We provide protection against electrostatic discharge for production rooms in which the floor is lightly loads. On the other hand, it is robust enough for the use of forklifts and pallet trucks.