An ESD Flooring system serves as a conduit for an electrical static charge (known as BVG or Body Voltage Generation accumulation on a person from movement across a surface) to discharge to a desired controlled ground point.

What is ESD flooring and anti static flooring?

ESD flooring, also referred to as anti static flooring, is a general term for flooring systems used in ESD sensitive environments. The electronic resistance value of ESD flooring is specified, which is between 2.5×104Ω and 1×109Ω.

According to the value, ESD flooring / anti static flooring can be divided into conductive flooring and static dissipative flooring.

What is conductive flooring?

In accordance with ASTM or EN test standard, the average electronic resistance value of conductive flooring is between 2.5×104Ω and 1×106Ω.. When flooring connect to the lower potential point, it will quickly discharge the charge.

What is static dissipative flooring?

In accordance with ASTM or EN test standard, the average electronic resistance value of static dissipative flooring is between 1×106Ω and 1×109Ω. When flooring connect to the lower potential point, it will slowly discharge the charge.

Why ESD flooring is needed?

ESD flooring / anti-static flooring is a simple way to prevent the accumulation of static on human body or equipment, through electrical connection between human body or equipment.

The floor surface provides an appropriate conductive path for the human body or equipment. Flooring is grounded through copper strips, which connect the flooring to grounded connections such as wall outlets. In this way, static accumulation can release.

Type of ESD flooring

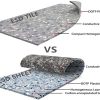

According to material differences, there are different types of ESD flooring, such as ESD vinyl flooring, anti static laminate, anti static rubber flooring, anti static ceramic, etc. Laminate, rubber and ceramic can only reach static dissipative(1×106Ω – 1×109Ω), while vinyl flooring can realize conductive(2.5×104Ω – 1×106Ω) which is permanent.

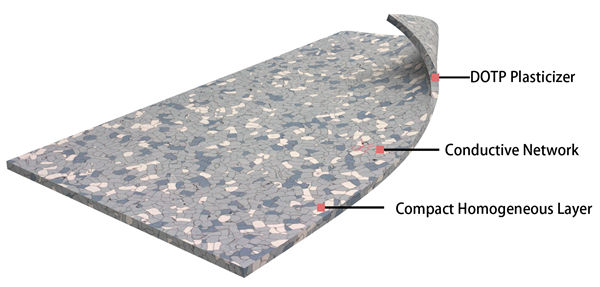

Different from other materials, ESD vinyl is homogeneous structure. Conductive particles are throughout the whole thickness, evenly distributed particles bring more stable and long-lasting conductivity.

In clean rooms, semiconductor workshops, electronic assembly workshops and other area with high anti static requirements, ESD vinyl flooring is the only and best choice.

How to install ESD flooring

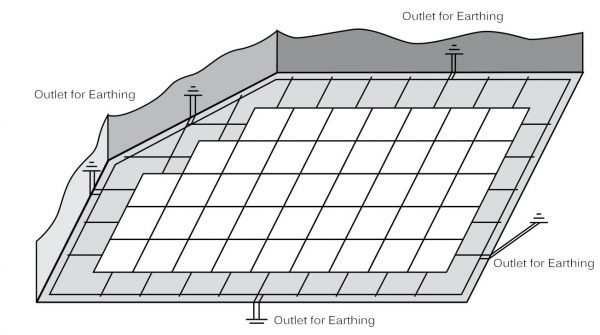

ESD flooring installation is the process of forming a conductive path between floor and ground. Professional accessories should be used, such as conductive adhesive, copper strips, etc.

Copper strip should lay under flooring flatly, the line connected to outlet for earthing should be long enough. When the laying arrives earthing places, lead copper strip out and connect to grounding terminal by soldering or crimping method.

ESD Flooring Installation Structure